Vätternpotatis

En av Europas modernaste fabriker för potatisförädling blir nu ännu mer modern

The mission

Vätternpotatis specialises in potato processing for large-scale catering and industrial uses. It is one of Europe’s most modern factories in its field and has been supplying potatoes for over half a century. The company was in dire need of an energy conversion as its former LPG combustion method is no longer environmentally sound.

Client:

Vätternpotatis

Industry:

Potato processing

Solution/Product:

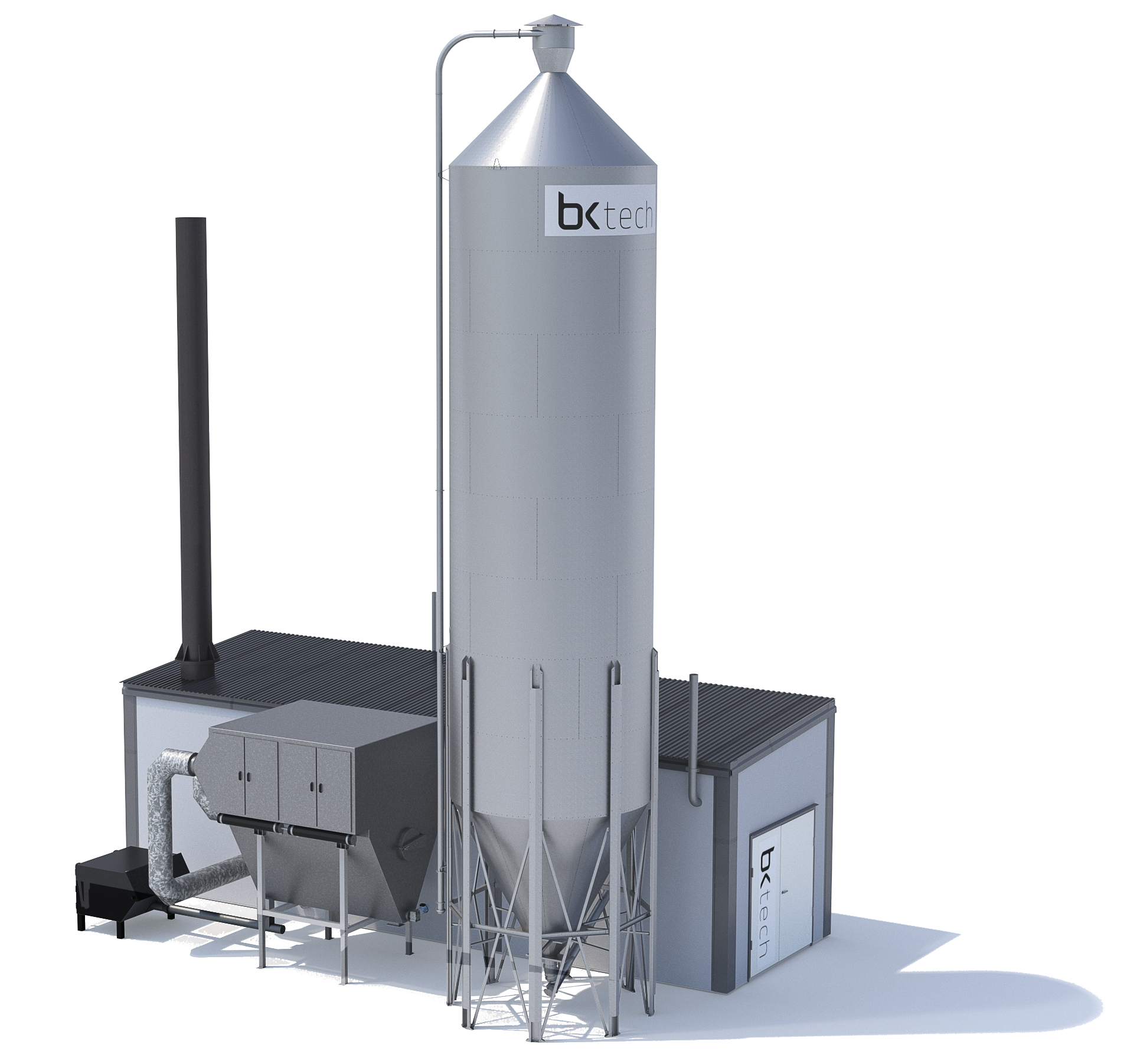

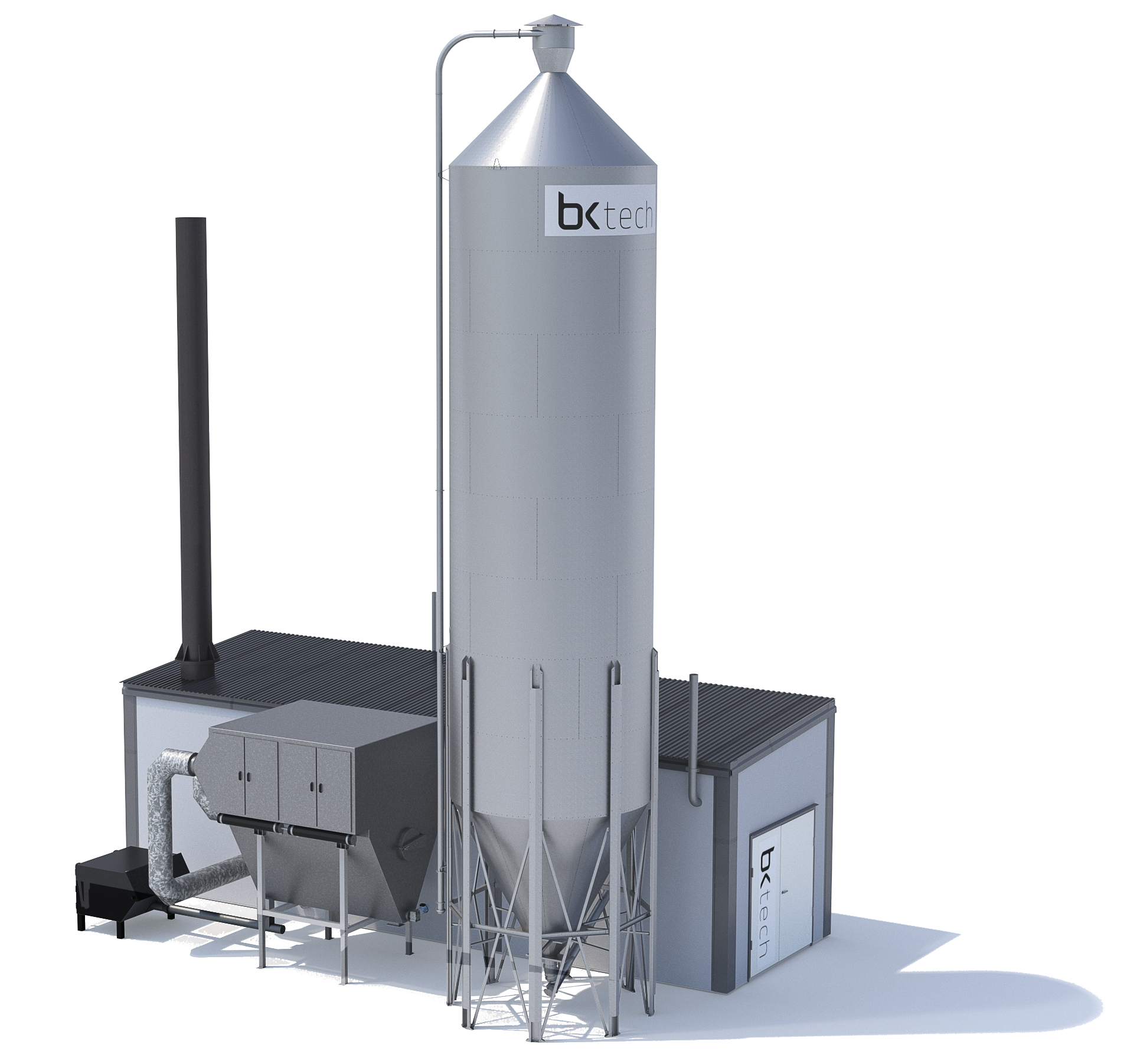

BKtech BioOne Steam 3 MW for steam production

Interesting facts:

Their sharply lowered CO₂ emission level of 1900 tonnes per year is equivalent to the annual emissions of 650 cars

The process

The former LPG combustion unit has been replaced with a modular bioenergy plant supplied by us at BKtech, with an output of 3MW and 31 bars. Potato processing requires exceedingly rapid load changes in steam production, something that is now handled very efficiently thanks to our BKtech-developed control system.

The results

Vätternpotatis’ potato production is now completely free of fossil fuels. Their energy-related costs have been drastically reduced, not to mention the mitigation of CO₂ emissions amounting to 1900 tonnes per year.

-93%

-65%

Generic fuel savings, not related to a specific reference case.

Any questions about the project?

Get in touch with:

Andreas Åström

Project Coordinator

Find out how much you can cut costs

By switching from fossil fuels to fossil-free bioenergy, you can benefit both the climate and your finances. Make a specific calculation for your company and find out how much you can save in terms of both CO₂ and budget.

Make your calculationMore cases from the food industry

”Lulles” – Ludvig Sörensen

Atria Borås

Falköpings Mejeri

Gudruns kött & charkuterier

Guldfågeln AB

High Coast Distillery

Krönleins Bryggeri AB

Nya Lantfågel på Österlen

Skövde Slakteri

Stranda Kyckling AB

Svenska Lantchips AB

Tevsjö Destilleri

Vätternpotatis

Wermlands Mejeri

Further companies that use our solutions